Min. / Max. pipe / profile length

100 – 15000 mm

Max. profile cross-section

500 x 500 mm

Min. diameter of a round pipe

Min. / Max. pipe diameter

10 mm

10 – 150 / 230 / 350 / 500 mm

Max. weight of the cut element

Max. system load

30 kg/m

3000 kg

Laser cutter

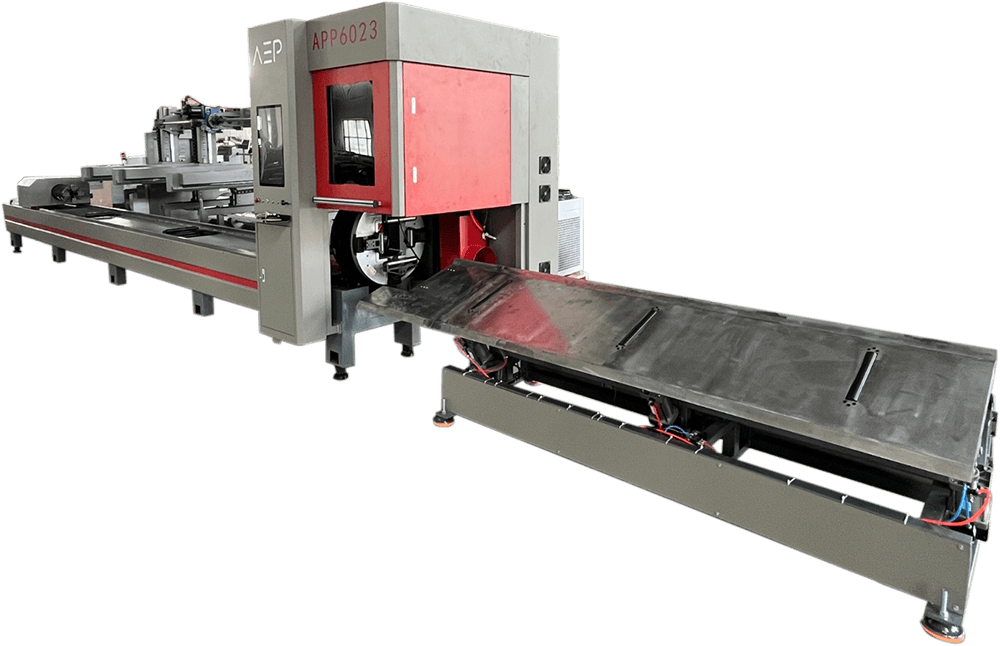

APP series

The APP series machine is a device dedicated exclusively to the processing of round pipes, open and closed profiles.

A rich base of optional elements

The device is standardly available in a manual version (individual side loading). However, this system has a very rich database of optional elements that will turn the APP into a fully automated unit with a feeder, synchronized loading and automatic recognition of the shape and size of the element to be cut.

The control system will automatically select the appropriate program from the internal database that matches the loaded profile.

The waste-free cutting system, which consists of four handles, is available as an option. The version with three handles (optional) allows processing of the profile along its full length, leaving only 100 mm of waste.

APP 6035

Basic parameters

Laser Head - AEP 421 / 442 / 462

Automatic autofocus frees the operator from setting the focal length, thus ensuring high repeatability of settings and minimal tolerance.

- Large range of focal length adjustment

The focus range is +10 ~ -10 with an accuracy of 0.01mm. - Variable head tip for cutting open profiles type C, H (for APP and APR)

The internal structure of the laser head is completely sealed to avoid dust contamination of the optical part. - Easy replacement of protective, collimating and focusing lenses, lenses are mounted in drawers,

- QBH connector

ACS – The collision protection system consists of several mechanisms thanks to which the machine should avoid contact between the head and the material. The whole system consists of:

- capacitive sensor with high dynamics - the sensor constantly measures the distance between the nozzle and the material and in the event of a deviation of 0.01 mm, it takes action and raises the head up

- software – the FS8000 software predicts places where the height of the cut element may change and places the head at the highest point when passing over the endangered area,

- mechanical protection – if the above two systems fail and the head hits the material; we secure the machine with the lower part of the head resting on screws with a predefined breaking point.

Functionality of heads by AEP:

ASK FOR DETAILS

Please contact us

Monday to Friday

at 07:00 am - 03:00 pm